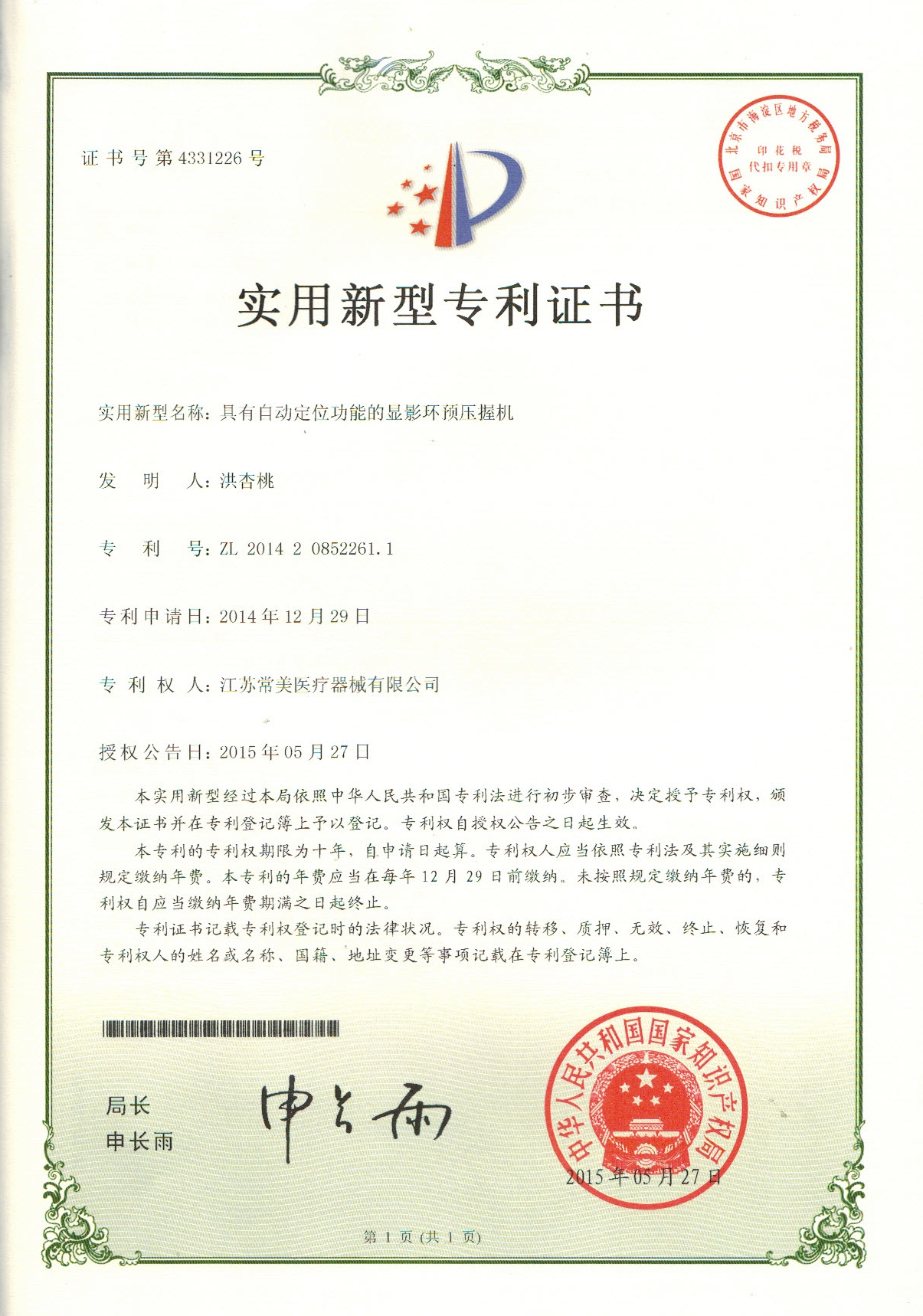

With automatic positioning function of developing the preload ring grip machine CN 204354486 U

The utility model provides a developer with automatic positioning function preload ring grip machine, comprising a base, PLC controllers, pressure grip mechanism and advancing mechanism, the advancing mechanism includes rails, sliders, fixtures, motors and ball screws Vice bars, the slide is fixed on said base, said slider fixture fixedly connected to said top, bottom rails connected to the slide, the ball screw comprises a screw and a nut screwed the screw at one end and the motor output shaft fixing this with automatic

positioning function of the developing ring preload control pressure grip grip ring development efforts by PLC controller to achieve fully automated, by a simple operation will be You can ring the developing accurate and reliable grip pressure to the catheter, the working efficiency, developing reliable fixed ring with the catheter.

An automatic positioning function having a developing preload ring grip machine, characterized by: comprising a base, PLC controllers, pressure holding means and advancing means, said advancing means comprises a rail, slider fixtures, motors and ball Ball Screw, the rail is fixed on the base, the top slider is fixedly connected to the clamp, the bottom of the slide rails connected to the ball screw comprises a screw threaded connection and nut, screw one end of the output shaft of the motor is fixed, the nut is fixedly connected to the slider, the PLC controller via the drive circuit connected to the motor, the pressure holding mechanism including through the PLC controller control expandable gripper closure pressure, the pressure and the clamp claw grip contour setting and the pressure hold is also provided with a connecting shaft between the jaws of the clamp.

2. The according to claim 1 having the function of automatic positioning of the developing machine grip ring preloading, characterized in that: the radial cross-section of the gripper claw opening pressure of a regular hexagon.

As claimed in claim 2 with automatic positioning function of the developing ring preload grip machine, characterized in that: the PLC controller is also connected to the control panel for manual operation.

4. 3 having the function of automatic positioning of the developing machine grip ring preload claim, wherein: said pressing means and the grip cover is provided with external PLC controller housing, the housing and the base fixed connection, said housing corresponding to the jaw with the mouth open for through-hole of the developing ring and connecting shaft protruded.

With automatic positioning function of developing the preload ring grip machine

Technical Field

[0001] The invention relates to the field of medical technology equipment, in particular relates to an automatic positioning function of developing the preload ring grip machine.

Background technique

[0002] With the development of medical standards, medical catheter has a special feature in the clinical and plays an important role. Wherein the catheter with visual development ring has been widely used, the developing Central pressure grip machine is a ring crush grip to the developing device catheter.

[0003] The conventional grip pressure using manual pressure grip, control efforts are not well, operational problems, and can not be accurately positioned grip pressure position, low production efficiency. Crimping grip machine can only hold a short press, there are limitations. Traditional press machine press gripper grip generally made of round or oval, can not effectively fix the developing ring.

Utility Model Content

[0004] The utility model technical problem to be solved is: In order to solve the existing development pressure grip ring operating problems, low productivity problems, the present utility model provides a developer with automatic positioning function preload ring grip machine to resolve the issue.

[0005] The technical scheme of the utility model for solving the technical problems are employed: one with automatic positioning function of the developing ring preload grip machine, comprising a base, PLC controllers, pressure grip mechanism and advancing mechanism, the propulsion mechanism comprises rails, sliders, fixtures, motors and ball screw, the rail is fixed on said base, said slide clamp is fixedly connected to said top, bottom and slidably connected to the slide, the ball screw includes a threaded screw and nut connected to the screw at one end and the motor output shaft is fixed, the nut is fixedly connected to the slider, the PLC controller is connected via the drive circuit and the motor the pressure holding mechanism including through the PLC controller may be opened gripper closure pressure, the press gripper and the fixture is set high and the pressure between the claw grip and the jig is also provided with a connection axis.

[0006] Advantageously, the radial cross-section of the gripper claw opening pressure of a regular hexagon.

[0007] Advantageously, the PLC controller is also connected to the control panel for manual operation.

[0008] Advantageously, the pressure holding mechanism and PLC controller external cover is provided with housing, the housing and the base is fixedly connected, said housing corresponding to the jaw with the mouth open and connected for developing ring extends into the shaft through hole.

[0009] The utility model has the advantages that such a development with automatic positioning ring preload control pressure grip grip ring development efforts by PLC controller to achieve fully automated, by a simple operation can be accurately developed ring Reliable grip pressure to the catheter, work efficiency, developing reliable fixed ring with the catheter.

Brief Description

[0010] The utility model further below in conjunction with the accompanying drawings and the description of embodiments.

[0011] FIG. 1 is a schematic structural view of the utility model with automatic positioning function of developing the preload ring grip preferred embodiment of the machine.

[0012] FIG. 2 is a schematic view of the automatic positioning of the new development preload ring grip machine grip pressure when operating the utility has.

[0013] FIG. 1, the base 2, the housing 3, screw, 4, slide 5, slider 6, the jig, 7, pressure gripper, 8, the connecting shaft 9, conduits, 10, I, developing rings.

DETAILED DESCRIPTION

[0014] The present utility model will now make a detailed description of the further figures. The figures are simplified schematic, only schematically illustrate the basic structure of the utility model, so it displays only the constitution and the utility model-related.

[0015] As shown, the utility model provides a 1 to 2 with automatic positioning function of the developing ring preload grip machine, comprising a base 1, PLC controllers, pressure grip mechanism and advancing mechanism advancing mechanism includes rails 4, the slider 5, 6 fixtures, motor and ball screw, the pressure holding mechanism and PLC controller external cover is provided with housing 2, the housing 2 is fixedly connected to the base I, the housing 2 corresponds to jaw with the mouth open for vias developing and connecting shaft 8 extends into the ring, the slide 4 is fixed to the base I, at the top of the slider and the clamp 5 6 fixedly connected at the bottom of the slide 4 slide connection, ball screw includes a screw threaded connection the output shaft 3 and the nut, screw 3 is fixed at one end and the motor, the nut is fixedly connected with the slide 5, PLC controller is connected via the drive circuit and the motor, the pressure holding mechanism comprises an expandable closure pressure controlled by PLC controller 7 claw grip, press gripper 7 and the holder 6 is set high and the pressure between 7 and clamp gripper 6 is also provided with a connecting shaft 8, PLC controller is also connected to the control panel for manual operation via the control panel to the staff When the PLC controller input command, making pressing grip, open the clamp 6 and the press gripper 7, will cover several months developing the ring conduit 9 arranged around the connecting shaft 8, for convenience of explanation, the pressure from the closest gripper 7 developing ring since I, in turn named a developing Central, 10,2 developing ring ...... then connect the shaft 8 from the jig 6 - for straight to the press gripper 7, closing pressure gripper 7 to gripping the connecting shaft 8, 9 continue to advance the catheter until the end of the catheter 9 top to press gripper 7 up, and then open the pressure control clamp gripper 7 and 6 clamped conduit 9 forward push, when I No. 10 to the developing ring 7:00 claw grip pressure, depending on the number 9 on the developing control loop catheter holder 6 from the next push, the purpose is to get all of the developing ring neatly arranged on the conduit 9 and stick close together, then open press gripper 7, fixtures 6 push forward development at a distance less than the axial length of the ring, press gripper 7 is closed again so gripping I, developing the ring 10, the jig 6 pulling back conduit 9, the purpose is to pull back I number 10 and the developing ring the distance between the rings on the 2nd developing over the axial length of the pressure gripper 7, and then turn the pressure gripper 7 and continue to push the clamp 6, the catheter 9 is located between I, section 10 and the 2nd developing ring ring can be developed 7 gripping claw grip pressure, and finally close the press gripper 7, gripping duct 9 to adjust the distance and I, developing ring 10 and the 2nd developing between the rings by a clamp 6, I, developing complete grip pressure ring 10 , and so to complete all the development pressure grip rings; press gripper claw opening 7 of the radial section of a regular hexagon, aimed at developing a better ring to a fixed position for accurate positioning pressure hold process.

[0016] In accordance with the present utility model above the ideal embodiment of inspiration, the contents of the above description, the relevant staff can without departing from the scope of this practical new technology ideas, carry out a variety of changes and modifications. The utility model of technical scope is not limited to the contents of the instructions on the need to be determined according to its technical scope of the claims.