Changmei Medtech

Balloon equipment (3)

All kinds of processing equipment which is related to the production of the balloon, including the balloon molding machine, neck stretching machine, welding machine, folding machine, pleating machine, ring forging machine, etc..

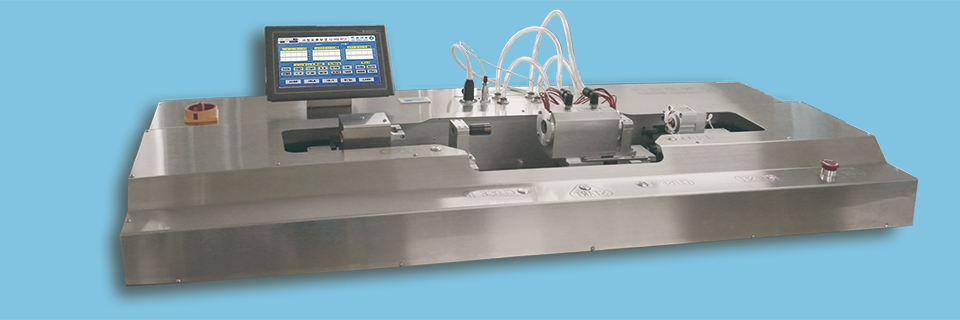

Features:

- 11"table with build-in PLC and forming data storage.One-key conversion when changing different mold;

- Visual charts for forming process including suck key parameters as temp,pressure,tension etc;

- Water-cooling design,20 sec from 150℃ to 25℃;

- Servo drive and digital tension respond applied in axial streching offer precise control over wall thickness and neck size of balloon;

- Resistive heater with dedicated PID control ensure fast heating&precise temp control;

- Unique prasion with rapid loading design(patent pending) only takes 10 sec to load an ordinary balloon parison;

- Balloon forming pressure by digital proportional valve can provide various pressure configuration according to different forming requirements.Pressure precision:around 1%.

Read 5240 times

Features:

- Auto pleating machine is mainly used in dilation balloon catheter to pleat the balloon along with the catheter center so as to inprove the passability;

- Simple PLC control provides easy operation to each pleating process;

- Accoring to the balloon size and material,the machine could adjust pleating pressure and setting temperature;

- After pleating the balloon could be covered directly under rotary form;

- After pleating,the diameter rang can be 2-40mm,and the longth rang can be 10-150mm;

- Number of wings:3,4,5,6.

Read 2949 times

Features:

- The machine is mainly used to crimp the metal ring into the surface of the plastic tube.The metal could be with radiopaque feature like platinum and silver,or stronger metal like stainless steel;

- With PLC control process,the machine could adjust rotary speed according to the material radiopaque marker;

- Adopting edgeless technology,the surface of metal ring is smooth and of no angularities;

- The machine could adjust depth of crimping into plastic tube according to the requirements of customers;

- Different crimping slice is selected accoding to the diameter of metal ring.It is easy to replace the slice to meet the requirements of customers.

Read 2732 times