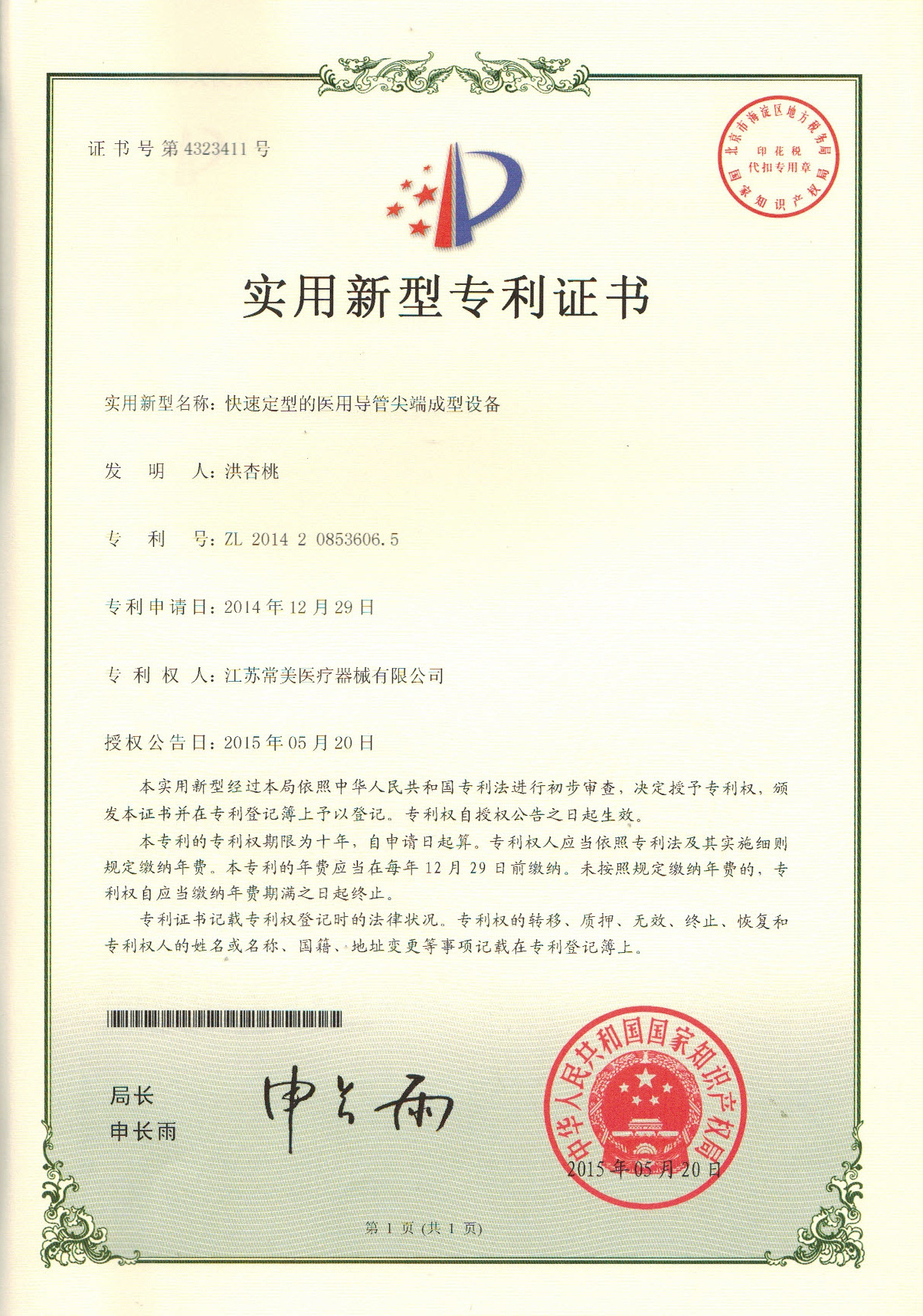

Fast setting medical catheter tip forming equipment CN 204340038 U

The utility model provides a fast setting medical catheter tip forming equipment, including console, PLC controller, the catheter tip mold and heating coils, the catheter tip mold detachable mounted on the operating table, The heating coil is provided around the periphery of the catheter tip forming die and the inner wall of the heating coil of the catheter tip with the outer mold to maintain the spacing, the PLC controller mounted in the operation of the heating station and coil is connected, this rapid medical catheter tip shape molding equipment using radio frequency heating of the medical catheter tip processing, high heating efficiency, the mold is heated evenly and improve the quality of molded products, and easy disassembly mold and console, to different models When the product is processed, the replacement of mold-saving, wide range of processed products and models, high efficiency.

A fast setting medical catheter tip forming apparatus comprising: a console, PLC controller, the catheter tip mold and heating coil, the catheter tip mold detachably mounted on the operating table a heating coil disposed around the periphery of the catheter tip in the forming die and the inner wall of the heating coil of the catheter tip with the outer mold to maintain the spacing, the controller is mounted on the PLC and the operator station heating coil is connected.

2. The fast setting medical catheter tip forming apparatus according to claim 1, characterized in that: further comprising a hollow mandrel positioned, the catheter tip forming die having a cavity for processing said tip catheters, the One end of the positioning mandrel inserted into the catheter tip and in communication with the mold cavity, the other end exposed outside the catheter tip mold.

3. The quick setting medical catheter tip forming apparatus according to claim 2, characterized in that: said catheter tip has two of said forming die cavities, said positioning mandrel and an amount of respectively the two said two of said cavity communicating.

The fast setting medical catheter tip forming apparatus according to claim 3, wherein: the operating table is also provided with two fixture, the two fixtures are located in the two positioning mandrel It exposed in the vicinity of one end of the catheter tip mold outside.

5. ~ 4 to any one of the fast setting medical catheter tip forming apparatus according to claim, characterized in that: the catheter tip mold and heating coil also has an aluminum cover plate.

6. The quick setting medical catheter tip forming apparatus according to claim 5, wherein: the aluminum cover plate is connected to the medical catheter tip for semiconductor cooling condenser.

7. The medical catheter tip rapid setting molding apparatus according to claim 6, characterized in that: said further attached to the catheter tip for detecting a temperature of the mold temperature sensor within the console, the temperature sensor and the PLC controller.

8. A molding apparatus as claimed in sophisticated medical catheter rapid setting according claim 7, characterized in that: said catheter tip mold made of stainless steel.

Fast setting medical catheter tip forming equipment

Technical Field

[0001] The invention relates to the field of medical equipment manufacturing technology, particularly to a fast setting medical catheter tip molding equipment.

Background technique

[0002] With the social and economic development, people's living standards continue to improve, clinical medical catheter is also rising. At present, China's rapid development of medical intervention, the rapid expansion of interventional medical tubing market, has become a high-tech and emerging industries, high value-added.

[0003] The medical catheter wide range of different uses for the catheter can better play the role in the clinic, the need for proper processing of the catheter tip. Because catheters complex shape, high health indicators, biochemical and high stability requirements, making medical catheter tip molding equipment requirements are high. Currently on the market a lot of the catheter tip forming device, the catheter tip mold and heating coil existing molding apparatus as a whole can not be demolished, the heating wire is wound directly on the catheter head mold, it is difficult to ensure that all the various parts of the catheter tip is heated evenly, affect product quality; and replacement of other models when you die, to die together with the product and all other ancillary components of the heating coil removed, time-consuming, reducing efficiency.

Utility Model Content

[0004] The utility model technical problem to be solved is: In order to solve the existing molding equipment for medical catheter tip various parts of uneven heating, affect product quality problem, the device of the present utility model provides a quick setting of catheters sophisticated molding equipment to solve the problem through radio frequency heating of processing methods.

[0005] The technical scheme of the utility model for solving the technical problem is adopted: a fast setting medical catheter tip forming equipment, including console, PLC controller, the catheter tip mold and heating coils, the catheter tip mold detachably mounted on the operating table, said heating coil provided around the periphery of the forming die catheter tip and the inner wall of the heating coil of the catheter tip with the outer mold to maintain the spacing, the PLC control installed in the operating station and is connected to the heating coil.

[0006] Advantageously, further comprising a hollow mandrel positioning the catheter tip mold cavity having a tip for the processing of the medical catheter, the positioning mandrel end is inserted into the catheter tip and the mold and said cavity communicating at the other end of the catheter tip exposed outside the molding die.

[0007] Advantageously, the catheter tip forming the mold cavity having two, the number of the two positioning mandrel and communicating respectively with the two said cavity.

[0008] Advantageously, the operating table is also provided with two fixture, the two fixtures are located near the outer end of the catheter tip mold forming the two positioning the mandrel exposed.

[0009] Advantageously, the catheter tip forming the mold and heating coil also has an aluminum cover plate.

[0010] Advantageously, the aluminum plate is connected with a cooling pipe for the semiconductor medical catheter tip cooling.

[0011] Advantageously, said console further installed with a temperature sensor for detecting the temperature of the catheter tip for the mold, said temperature sensor is connected to the controller PLC.

[0012] Advantageously, the catheter tip mold made of stainless steel.

[0013] The invention has the advantages that this rapid medical catheter tip shape molding equipment using radio frequency heating of the medical catheter tip processing, high heating efficiency, the mold is heated evenly and improve the quality of molded products, and mold and Station to facilitate the demolition, when different types of products for processing, saving time and effort when changing the mold, a wide range of processed products and models, high efficiency.

Brief Description

[0014] The utility model further below in conjunction with the accompanying drawings and the description of embodiments.

[0015] FIG. 1 is a schematic view of the preferred embodiment of the present utility model is fast setting medical catheter tip molding equipment.

[0016] FIG. 2 is a partial structural diagram of the utility model catheters quick tip shape molding equipment.

[0017] FIG. 1, console, 2, catheter tip mold 3, the heating coil 4, the positioning mandrel, 5, fixture, 6, aluminum plate, 7, the temperature sensor.

DETAILED DESCRIPTION

[0018] The present utility model will now make a detailed description of further figures. The figures are simplified schematic, only schematically illustrate the basic structure of the utility model, so it displays only the constitution and the utility model-related.

[0019] As shown in Figure 1 to 2, the utility model provides a quick medical catheter tip shape molding equipment, including console 1, PLC controller, stainless steel catheter tip forming die 2 and the heating coil 3, the catheter the tip of the forming die 2 is detachably mounted on the console of formula I, heating coil 3 provided in the catheter tip about the periphery of the forming die 2 and the inner wall of the heating coil 3 and the tip of the catheter outer mold 2 is kept spaced, PLC controller mounted Station I and 3 in connection with the heating coil. This rapid heating coil shaped medical catheter tip forming apparatus 3 2 is not in contact with the catheter tip mold, high heating efficiency by radio frequency heating system makes rapid prototyping of medical catheter tip, the catheter tip forming die 2 is heated evenly, to ensure that products processing quality, and the heating coil 3 will not damage the mold.

[0020] This rapid shape molding medical catheter tip positioning device further comprises a hollow mandrel 4, the catheter tip has two cavity mold 2, Number 4 may be used for processing two medical catheter tip positioning mandrel for two, one end of the positioning of the catheter tip mandrel 4 die 2 and in communication with the cavity, the other end exposed to the outside of the catheter tip forming die 2, on the table I also provided with two fixture 5, two fixture 5 are positioned near the end of the two exposed mandrel 4 in the catheter tip 2 outside the mold; two catheter tip blanks are positioned from the ends of the two rod 4 penetrates and extends to the cavity , followed by five pairs catheter fixture is fixed billet, which can improve the stability of the processing pipe billet, to ensure the quality of molded products.

[0021] The catheter tip forming die 2 and the heating coil 3 also has an aluminum cover plate 6, 6 are connected to an aluminum cover for medical catheter tip cooling pipe semiconductor cooling than conventional air cooling methods common to quickly and effectively.

[0022] I also installed inside the console temperature sensor detects the temperature of the catheter tip forming die 2 for 7, the temperature sensor 7 is connected with the PLC controller, if the temperature sensor 7 detects the device temperature is too high, it will promptly notify the PLC The controller, which quickly cuts off the heating, ways to prevent accidents.

[0023] In accordance with the present utility model above the ideal embodiment of inspiration, the contents of the above description, the relevant staff can without departing from the scope of this practical new technology ideas, carry out a variety of changes and modifications. The utility model is not limited to technical scope of the Prospectus on, it must be determined according to the technical scope of the claims O frri Τ7Ί t- Ί-1